Twin Tray™ Sorter System

If you’re looking for an efficient and reliable way to sort and transport items in your facility, you’ve come to the right place. Mantissa is a leading manufacturer and supplier of high-quality material handling solutions, and our twin tray sortation system is one of our flagship products.

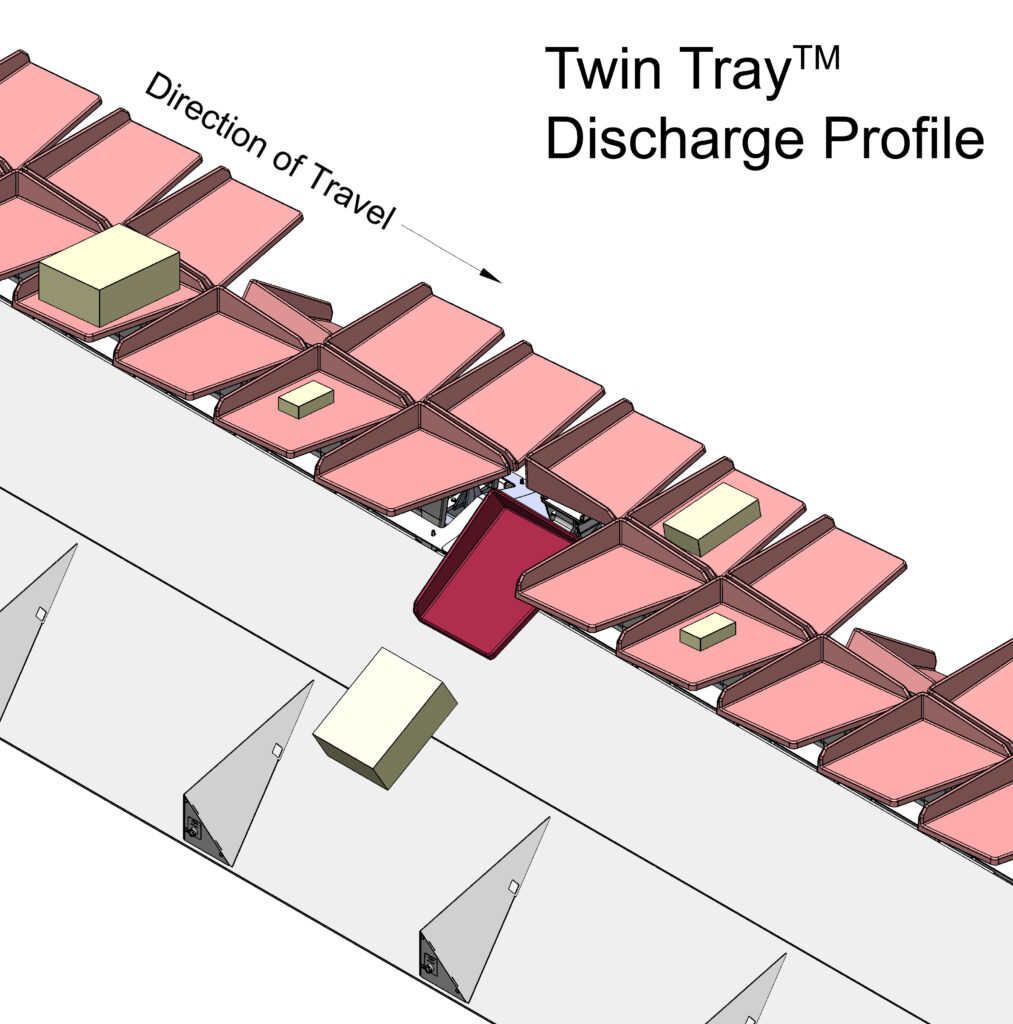

Our Twin Tray™ Technology

Mantissa’s Traditional Twin Tray™ Sorter utilizes the latest Third Generation Scorpion® sorter Platform. Built to be dependable and reliable, with simplicity in design. The Twin Tray™ is purposefully designed to provide the ultimate in throughput capabilities. Mantissa Twin Tray™ systems have been installed that provide 100,000 UPH, and can handle bags and boxes, which range from 3”sq to 36” long, and 6oz. to 150Lbs. Tray size and pitch are configured to average product sizes, as larger items can be handled across multiple trays. High throughput capacity can be achieved with multiple pitch configurations and operating speeds of up to 2.3m/s, while maintaining a less than 70db operational environment.

Twin Tray™

The Mantissa Twin Tray™ is utilized to allow tipping on both sides of the sorter simultaneously, allowing flexibility in meeting system requirements while providing superior product handling. To handle the unique characteristics of your product, Mantissa custom designs the Twin Trays to best transfer that product to its discharge location.

Benefits of the Twin Tray Sortation System

There are many benefits to using the Twin Tray Sortation System in your facility, including:

- Improved productivity: The system is designed to handle high volumes of items quickly and efficiently, reducing the time it takes to sort and transport goods.

- Increased accuracy: With the ability to sort items into designated chutes or bins, the system reduces the risk of errors and improves order accuracy.

- Reduced labor costs: By automating the sorting process, the system can help you reduce labor costs and improve efficiency.

- Customizable: The system can be customized to fit your specific needs, with options for tray size, material, and configuration.

Continuously sorting diverse products in diverse locations all over the world. The Mantissa Traditional Tilt-Tray truly is “Sortation Simplified”.

How Does the Twin Tray Sorter Work?

Items are inducted onto each tray, The Twin Tray™ allows independent items to be placed on adjacent trays. Trays can be tilted independently, providing double the sortation throughput of a single tray solution. Typical orientation for a single tray load is the longest dimension placed perpendicular to the sorter travel (Cross-Loaded). When the item reaches its destination, the tray is tilted to release the package. The tilting action is controlled via a 24vdc patented cascade free Tiploc™ mechanism. Through this mechanism, variations in tilting speed due to product placement or product weight are eliminated, allowing a more accurate and fluid tilting action.

Why Choose Mantissa?

At Mantissa, we are committed to providing our customers with the highest quality material handling solutions on the market. Our Twin Tray Sortation System is designed and manufactured in-house, using only the best materials and components to ensure reliable performance and long-lasting durability.

We also offer a range of services to support our customers, including installation, training, and ongoing support. Our team of experienced technicians is always available to answer your questions and provide assistance when you need it.

If you’re interested in learning more about Mantissa’s Twin Tray Sortation System, contact us today to schedule a consultation with one of our experts. We look forward to working with you!